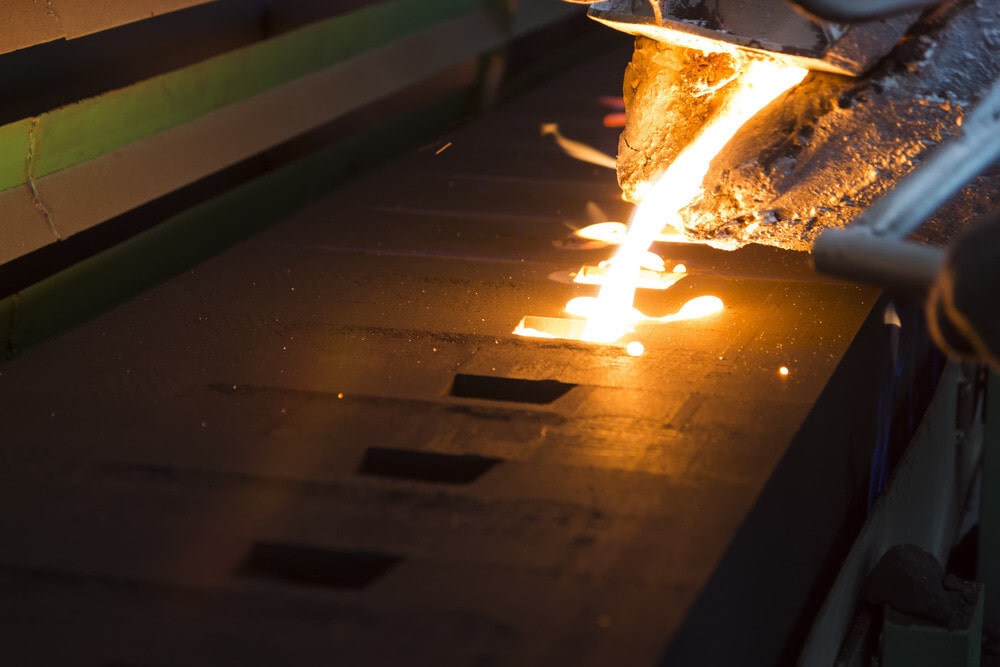

The casting system executes a steel shape frequently fit for delivering a huge number of castings in fast progression. The die should be made in no less than two segments to allow expulsion of castings. The casting cycle starts with the two die parts clipped firmly together by the die-casting press. Liquid aluminum infused into the die cavity where it cements rapidly. These segments mounted safely in a machine and organized with the goal that one is fixed while the other is moveable.

Casting dies

The die parts drawn separated. And the casting launched out. Casting dies can be straightforward or complex, having moveable slides, centers, or different segments relying upon the intricacy of the casting. Most machines use systems impelled by hydraulic powered chambers to accomplish locking. Others utilize direct acting water powered pressure. Casting machines, huge or little, in a general sense just in the technique used to infuse liquid metal into the die. aluminium pressure die casting manufacturers India

WHAT ARE THE Upsides OF ALUMINUM CASTING?

There are many reasons aluminum is the most generally projected non-ferrous metal on the planet. As a lightweight metal, the most famous justification behind using aluminum casting is that it makes extremely lightweight parts without forfeiting strength. Aluminum die cast parts additionally have more surface completing choices and can endure higher working temperatures than other non-ferrous materials.

Solidness

Aluminum die cast parts are erosion safe, profoundly conductive. It have a decent solidness and solidarity to-weight proportion. The aluminum casting process depends on fast creation that permits a high volume of die casting parts to delivered rapidly and more expense successfully than elective casting processes. Aluminum die casting has turned into the inclined toward choice for purchasers around the world.

Qualities and Benefits of Aluminum Castings include:

Lightweight and Solid

Great Solidarity to-Weight Proportion

Extraordinary Protection from Consumption

Phenomenal Electrical Conductivity

Completely Recyclable and Reusable Underway

CASTING Assembling HISTORY

die casting mold The history of Die Casting started in the mid 1800’s. With the main die casting hardware being utilized for the Printing Business. This innovative headway at the time was gainful to make a versatile item. During the extended period of 1849, Sturges procured a patent for the creation of the principal little hand physically worked machine intended for casting printing type.

Extraordinary Castings

These extraordinary Die Castings were planned to fabricate an assortment of easy to complex shapes while having an elevated degree of exactness, imagination, and a constant cycle to procure an incentive for the items. In the later long stretches of 1855, fostered the linotype machine that turned out to exceptionally famous and proficient piece of hardware utilized in the distributing business.

The development of the great volume of creation

An overwhelming interest in the creation of business die casting filled in the mid nineteenth 100 years because of the development of the great volume of creation in different ventures. This development opened up various business sectors for the Die Casting Industry to venture into numerous assorted activities. During this advancement period.

Underlying metals of Tin and Lead

Aluminum and Zinc Die Casting Creation assumed control over the underlying metals of Tin and Lead because of the greater quality elements acquired by these items. The first course of low-pressure infusion die casting changed to the high-pressure casting technique because of modernized surface getting done and effective creation factors.

Die casting process

Since the beginning of time, all significant items make through die casting processes. And have zeroed in on saving organizations a lot of cash underway. Buyers can depend on steady outcomes, strong life expectancies, and dependably completed castings for their business and modern necessities relying upon the interest. Great View Exploration has announced that the Die Casting Industry is the biggest cycle fragment in the market representing 49.7% of worldwide offers in 2016 monetary year on account of minimal expense creation rates and consistency.

ALUMINUM CASTING Item Division

The ubiquity of aluminum has extended to numerous applications all over the planet today. Driving cutthroat pieces of the pie basically for its unmistakable highlights like lightweight. Consumption opposition, high electrical and warm conductivity. high soundness for complex shapes. And high elasticity. The transportation area is the biggest end-use portion for this industry. The rising emanation regulations by the public authority administrative specialists.

Aluminum casting

Alongside shopper interest for a higher eco-friendly vehicle is fostering a need for aluminum casting. An illustration of expanded tasks for the business remembers the substitution of iron. And steel parts for a vehicle with lightweight great aluminum to build the eco-friendliness. The Aluminum die-cast item is great for electronic connectors. And lodgings die to its superb electrical presentation and protecting properties, even in high-temperature conditions.

Building and development

Another area with respect to the aluminum die casting request remembers building. Development for creating economies especially in the Asia Pacific locale. Aluminum Die Casting is related with the formation of items including windows, cladding, drapery walling. Pre-assembled structures, shop allotments. And fittings. Likewise, aluminum die casting items utilized in aviation tasks. Or planes from one side of the planet to the other. The airplane business needs to create a more thick. And bigger quality item at lower costs for these air-outline parts as airplane keep on filling in size alongside populace rates.